WHAT WE DO

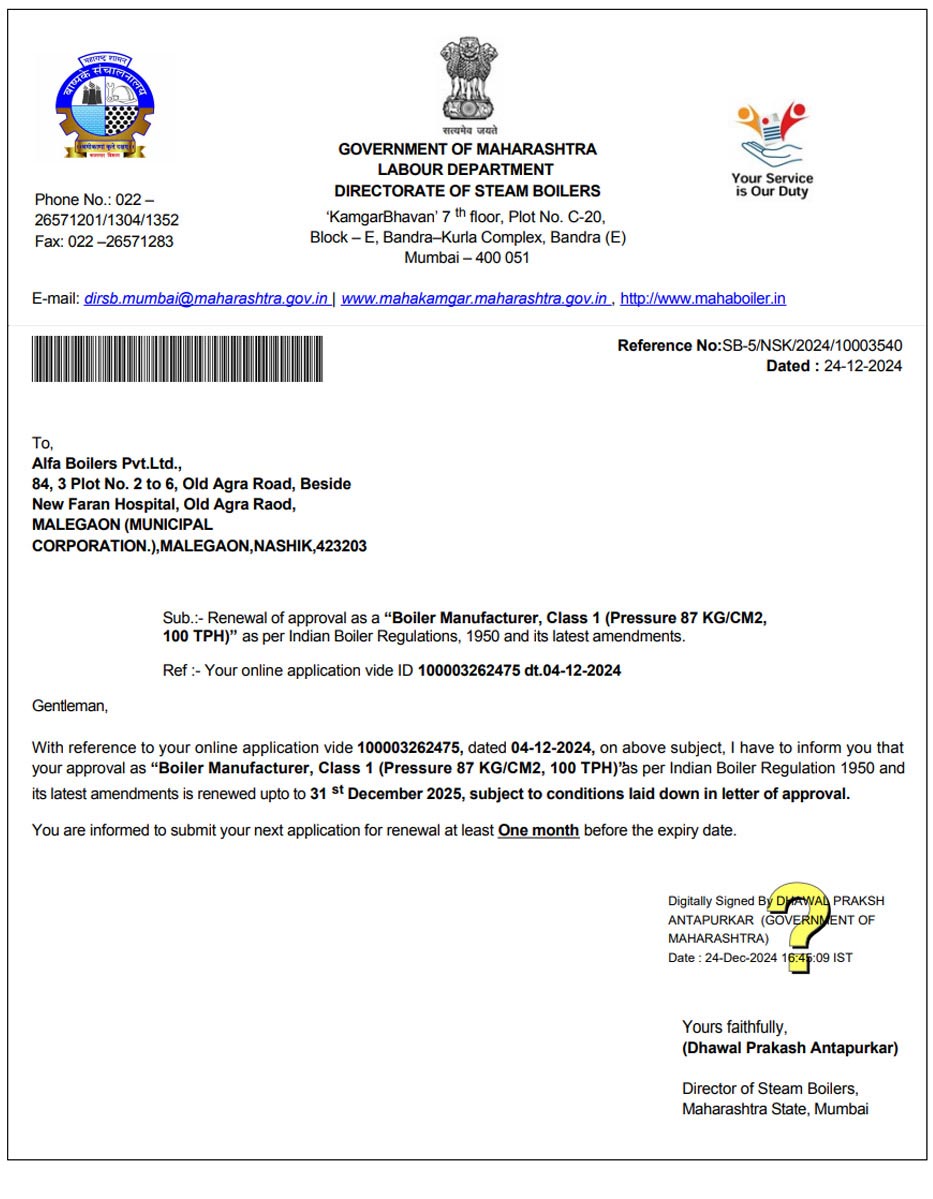

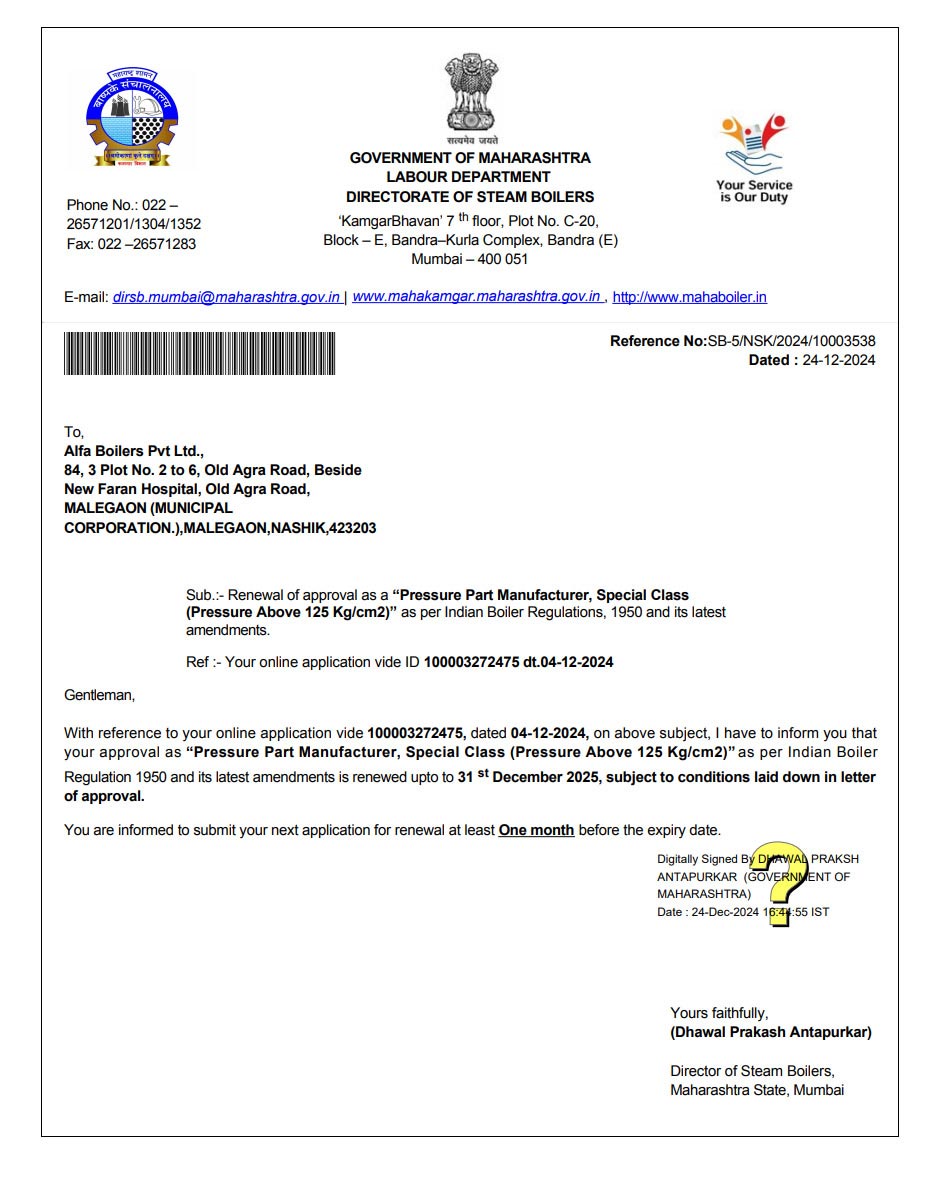

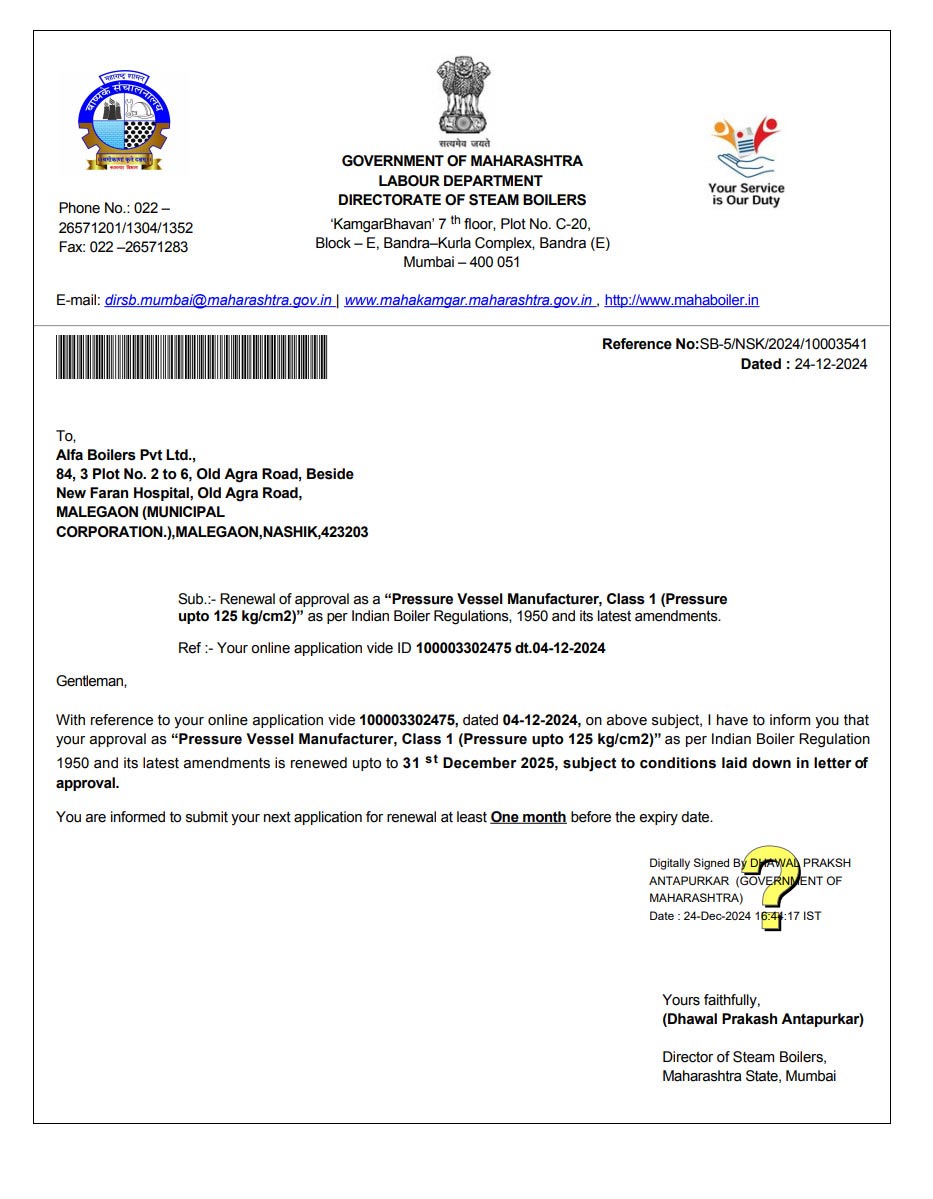

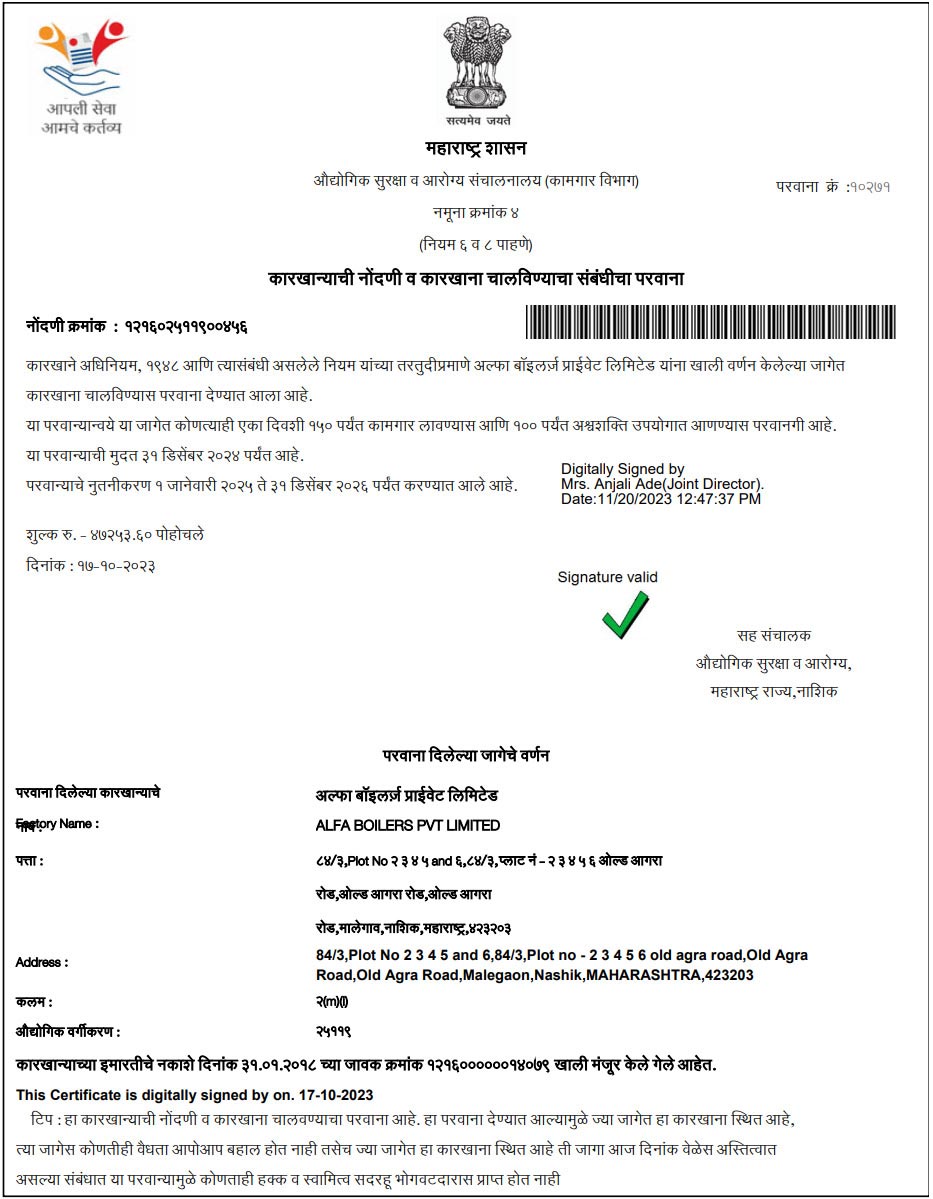

ABPL manufactures and supplies Boiler for process and power industries on Engineering, Procurement and Construction (EPC) basis. Pressure Parts like Studded Bed Coils, Economizer Coils, Super Heater Coils, Evaporator Coils, Bank Tubes, Headers, Water Wall Panels, Bed Ash Coolers, etc., Today ABPL is providing services to the major clients such as NTPC, SAIL, CESC LIMITED, CESB, TATA POWER, HINDALCO, SHREE CEMENT, ULTRATECH CEMENT, CENTURY CEMENT, JK CEMENT, VICAT SAGAR CEMENT, DALMIA CEMENT, AMBUJA CEMENT, ACC, IOCL, JSW, JUBILANT LIFE SCIENCES, GRASIM INDUSTRIES, GAIL (I) LTD, JINDAL STEEL, BHUSHAN POWER, INLAND POWER, etc. and OEM’s such as THERMAX, WALCHANDNAGAR INDUSTRIES, THYSSENKRUPP INDUSTRIES, TRANSPARENT ENERGY, CHEEMA BOILERS, etc. with repeated orders from them. ABPL supplies boiler pressure components for utility power projects up-to 500 MW and is one of the largest manufacturers of studded bed coils in India. Since 1995, ABPL gained valuable experience in manufacturing of boiler components and today ABPL upgraded itself by supplying Boiler for process and power industries on Engineering, Procurement and Construction (EPC) basis.

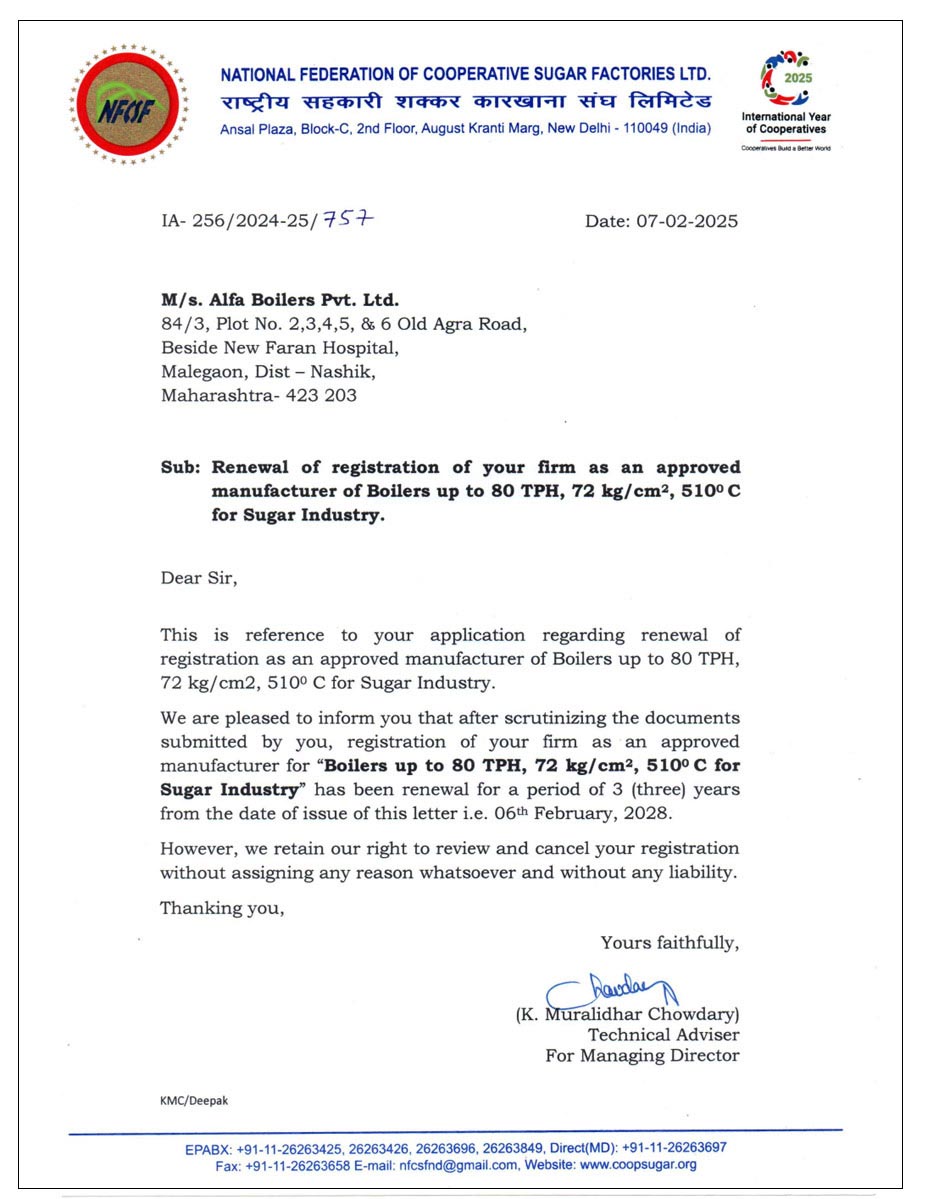

ABPL is fully equipped for supplying boilers up-to 100 TPH and pressure up-to 125 kg/cm2 (g) for all types of fuels. Recently ABPL manufactured and supplied agro waste fuel based boiler having generation capacity of 72 TPH with super heated steam pressure of 72 kg/cm2 (g) at 500 deg-C. ABPL is now focusing on turnkey projects of Boilers.